OUR HISTORY

Our History

Our machine and fabrication shop history spans over 50 years supplying quality steel components and assemblies to diverse industries including agriculture, construction, food processing, oil/gas, data protection, healthcare, and transportation. At EK, we proudly ship our products throughout the Midwest and the U.S. to a worldwide marketplace.

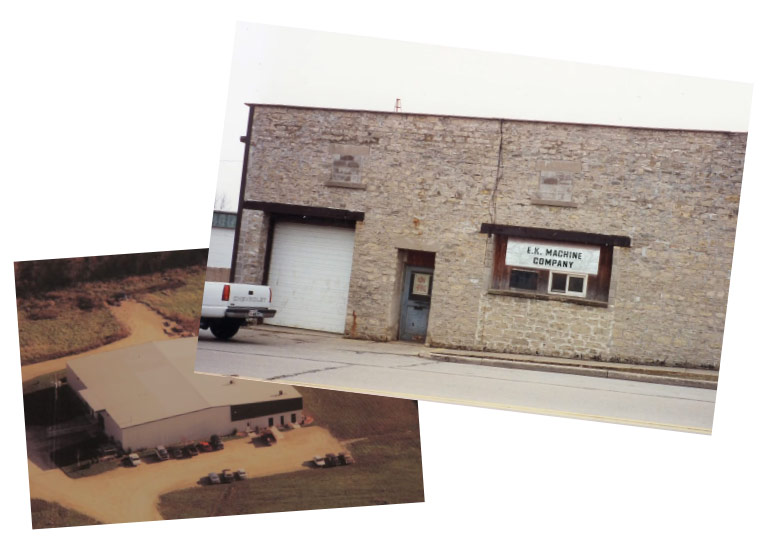

Founder, Gary Errthum started EK in 1970 because he wanted to keep his services local and spend more time with his family. The small machine and fabrication shop offered customized machining services for local farming, construction, food equipment, and trucking companies. Soon, companies from around the area took notice of the quality work offered by EK and began contracting more complex machining and fabrication services. To meet the demand, Errthum purchased and renovated a former brewery building to accommodate additional machining and welding capabilities. Over the next 20 years, that building grew to over 10,000 sq. ft. to accommodate 20 additional employees and new CNC machining and sheet metal fabrication capabilities.

1990 – 2009

By 1990, EK had again outgrown their facilities in Columbus, WI, and erected a new 20,000 sq. ft. plant in nearby Fall River, Wisconsin. In the following 10 years, the business continued to expand and our facilities grew with it, increasing to 57,000 sq. ft. that now included laser, CNC precision forming, and robotic welding. The EK team also acquired a second facility to incorporate powder coating paint capabilities into its customer offerings.

As business and demand continued to grow, EK took on new employees, continued to expand its capabilities, and, by 2007, the Fall River plant had increased in size to 115,000 sq. ft. with the addition of in-house powder coating and a new, state-of-the-art welding department. New corporate offices were completed in 2009 to keep up with customer service.

2010 – 2020

In 2014, EK fully expanded into the power system protection sector with the completion of a 55,000 sq. ft. Power Products facility, specially designed to accommodate large-scale, heavy-duty power generation equipment.

By 2019, we completed a 51,000 sq. ft. addition to our Power Products facility to meet the growing demand for our generator enclosures, trailers, fuel tanks, and ISO containers. With one of the largest storage yards in the industry, our Power Products facility includes diesel and natural gas testing stations, heavy-duty crane systems, a large-scale enclosure lift, state-of-the-art CNC equipment, and kitting capabilities to meet the needs of our clients, near and far.

To date, our EK team consists of nearly 200 team members across three shifts. We continually invest in capital equipment upgrades and additions and training and professional development opportunities to ensure our facilities and our people are empowered to make the best parts, components, and power system protection products on the market.

A Proven Track Record of Excellence

Throughout our time serving customers from Wisconsin and across the globe, we’ve been honored with a number of awards recognizing our manufacturing excellence and dedication to the craft. We’re proud and humbled by this recognition and will continuously work to meet these standards, again and again.

Columbus Chamber Of Commerce Manufacturer of the Year

Germania Quality Achievement Awards

Columbia County Manufacturer of the Year Award

State of Wisconsin Manufacturer Award

DeLaval Outstanding Performance Award

ISO 9001-2000 Certification

Monroe Truck Preferred Supplier Award

ISO 9001-2008 Certification

Columbia County Large Business of the Year

Wisconsin Manufacturer of the Year “Workforce Development”